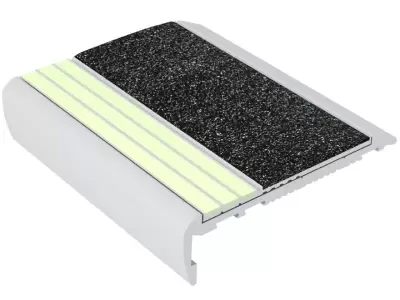

F7-E40 Luminescent Flat Stair Nosing IL-F7-E4

Product successfully added to the Quote List

- Payment by invoice possible

- In stock at factory, ready to ship in estimated 1-2 weeks, contact us for expedited options

- Del Rey is proud to be the exclusive distributor of iLumiGlo products

- Del Rey is proud to be the exclusive distributor of Waagene products

- Payment by invoice possible

- Low quantities typically kept on hand; please contact us for availability at lead time

- Authorized MiniBOOSTER distributor & hydraulic excellence partner

Product Description

Our high performance F7-E40 Photoluminescent Anodized Flat Stair Nosing provides step edge visibility and enhances egress speeds in all lighting conditions, creating a safe, and efficient egress path in any facility. Our stair strips can be installed on a range of materials to meet the needs of any project, including concrete, timber, steel, tiles, and checker plate stairs. Alone, this product brightly illuminates stairways in any egress pathway, and can be used in conjunction with illuminated exit signs in order to create a safe path to the exit discharge of any facility. Through providing step edge contrast, stellar visibility in all light conditions, slip resistance, and wear-resistant, Ecoglo®’s F7-E40 Photoluminescent Anodized Flat Stair Nosing will provide your facility with a four-pronged solution to pathfinding needs. Our non-slip stair nosing not only meets code compliance, but exceeds luminous egress requirements set out in local and international building, fire and life safety codes. The safety of all people in a facility depends on a clear egress plan and advance site preparation including clear marking of escape routes. Photoluminescent egress marking systems installed in exit stairwells are a critical, code-required component of any building safety system. Photoluminescent markings are always on, full proof systems to guide people out of buildings during any type of emergency conditions. Charges with ambient light. Always-on visible light. No electricity required. Our photoluminescent systems are comprised of materials including aluminum, epoxies, PVC, tapes, and paints . A one-inch wide “glowing” stripe is applied to the leading edge the steps, on handrails, and along the perimeter of landings and pathways leading out of the building. General Information Install these stair strips with polyurethane adhesive and mechanical fasteners, or solely adhesive. We supply these products with pre-drilled countersunk holes for your convenience, including stainless steel fasteners and concrete nylon anchors. The standard location for these holes is 2” from each end and approximately 12” apart. The standard lengths of our stair strips are 8ft and 10ft, but they are also available in cut-to-length sizes (Tolerance + or – 1/8”) Inserts are supplied unattached but will be easily installed over the mechanical fasteners using a polyurethane adhesive (which is included). Inserts can be cut using a shear, while aluminum nosings are cut with a saw. Do not cut inserts with a saw as it will damage the saw blade. Weight: 0.416 lbs/ft. Aluminum Finish Available in Clear Anodized Aluminum Finish Black, Light Bronze and, Dark Bronze Anodize finishes are available at an additional cost

Additional information

Product specification

- Install these stair strips with polyurethane adhesive and mechanical fasteners, or solely adhesive.

- We supply these products with pre-drilled countersunk holes for your convenience, including stainless steel fasteners and concrete nylon anchors. The standard location for these holes is 2” from each end and approximately 12” apart.

- The standard lengths of our stair strips are 8ft and 10ft, but they are also available in cut-to-length sizes (Tolerance + or – 1/8”)

- Inserts are supplied unattached but will be easily installed over the mechanical fasteners using a polyurethane adhesive (which is included). Inserts can be cut using a shear, while aluminum nosings are cut with a saw. Do not cut inserts with a saw as it will damage the saw blade.

- Weight: 0.416 lbs/ft.

Aluminum Finish

- Available in Clear Anodized Aluminum Finish.

- Black, Light Bronze and, Dark Bronze Anodize finishes are available at an additional cost.

Nosing Engineered for Durability:

- Ecoglo®’s patented manufacturing process produces highly efficient and the most durable photoluminescent stair strips on the market.

- Our team designed unique ridges in the photoluminescent strips to protect it from most abrasive damage.

- We have bonded the aluminum substrate of this product to the resilient silicon carbide non-slip material so that it can withstand the rigors of thousands of people walking on it without showing any signs of wear and tear.

- The thick anodized finish of our product is aesthetically pleasing, prevents corrosion, is abrasion resistant and extremely hard. The anodized aluminum surface of this pathfinding solution is also harder than pure aluminum – second only to the hard-crystalline structure of diamonds.

Superior Step Edge Safety:

- The color contrasting the non-slip material with the stair strips’ advanced photoluminescent technology provides clear step edge visibility in all light conditions.

- Effective wet or dry – the unique ridges in the Ecoglo® photoluminescent strips and the integrated anti-slip contrast strips provide stellar resistance in all weather conditions.

For Indoor Use and Outdoor Use:

- We tested our stair strips under accelerated UV/weathering exposure and have proven them to be highly resistant to UV/weathering effects.

- When subjected to 6,000 hours of accelerated UV exposure, which is equivalent to 30 years of outdoor exposure, the loss in our stair product’s performance was less than be detected by the human eye.

- Our team uses a “long chain” polymer in Ecoglo®’s patented manufacturing process to create a strong UV-resistant product suitable for your use.

Environmentally Friendly Luminescent Aluminum Flat Stair Nosing:

- LEED points certified. Ecoglo® stair strips are energy efficient and will improve the environmental sustainability of your building.

- Our stair nosing details draw energy from existing lights in the building, and as such consume zero energy.

- This product is non-radioactive and non-toxic – a core trait in all Ecoglo® products.

- Our Flat Stair Nosings can also be easily recycled with no disposal cost, on top of having a long lifespan.