31

Oct

Mini Boosters in ROV Applications: Essential Hydraulic Solutions for Offshore Operations

Table of Contents

- The Offshore Environment: Demanding and Unforgiving

- Remote Operated Vehicles (ROVs): A Critical Tool in Offshore Operations

- 1. Types of ROVs

- Why Mini Boosters are Ideal for ROV Applications

- 1.Benefits of Using Mini Boosters in ROVs

- Applications of Mini Boosters in ROV Operations

- ROV Usage in the Oil and Gas Industry

- Hydraulic Tools Powered by Mini Boosters

- Corrosion Resistance and Durability

- ROV Market Growth

- Energy Efficiency and Cost Savings with Mini Boosters

- Extreme Depth Capabilities

- The Future of ROV Technology and Mini Boosters

- References

The Offshore Environment: Demanding and Unforgiving

Offshore oil and gas rigs represent one of the most challenging environments in the world. The average depth of offshore oil rigs can range from 100 meters to over 3,000 meters (328 feet to 9,842 feet), with deep-sea operations often extending into waters over 1,500 meters deep.At these depths, water pressure reaches 150 bars (2,175 psi), putting tremendous strain on any submerged equipment.

Trending Insights

Products Categories

Saltwater poses another challenge, leading to rapid corrosion of traditional metals. Constant exposure to saltwater can degrade equipment quickly, making corrosion-resistant materials, such as stainless steel, essential for subsea operations. Mini boosters, built with corrosion-resistant materials, are particularly effective in these environments, ensuring that ROVs can operate efficiently without succumbing to corrosion over time.

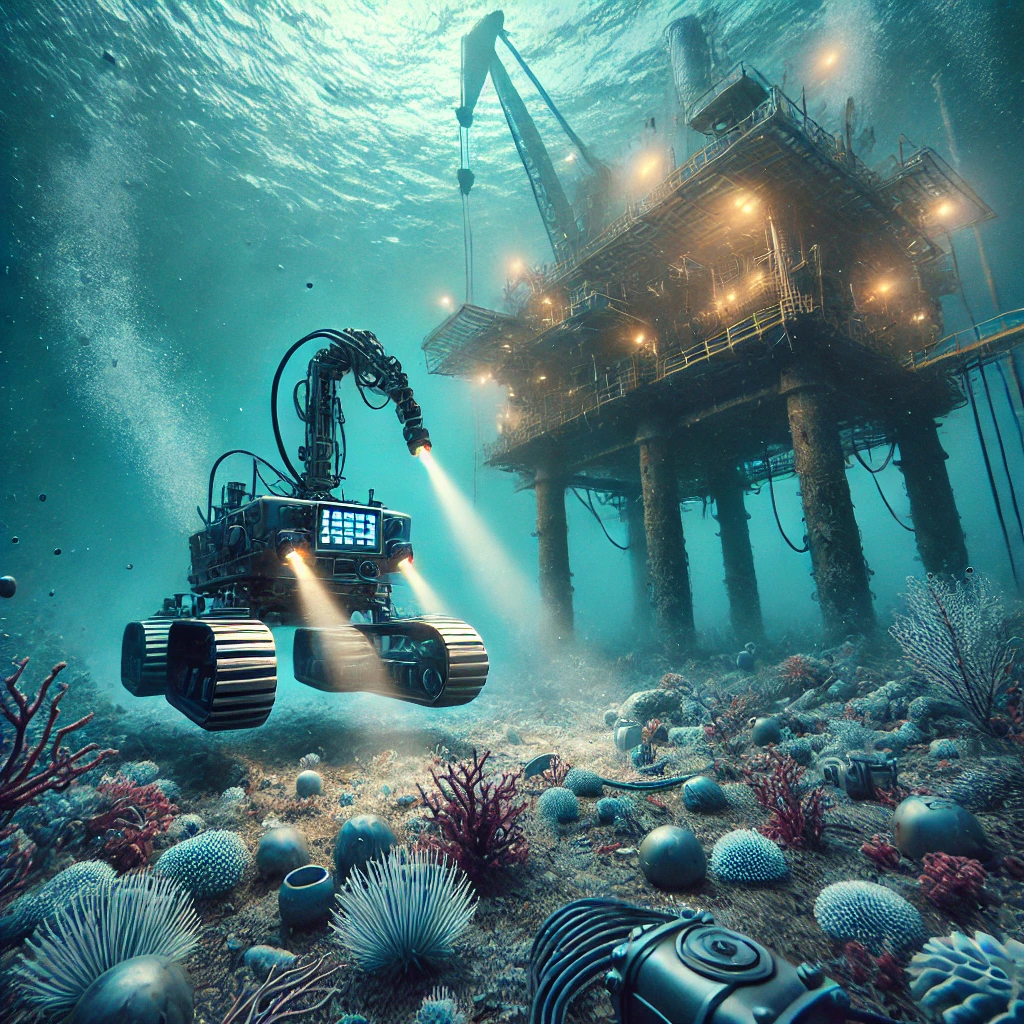

Remote Operated Vehicles (ROVs): A Critical Tool in Offshore Operations

ROVs, or unmanned submarines, are pivotal in maintaining the submerged sections of offshore oil rigs. These vehicles are remotely controlled from the surface, allowing operators to inspect and maintain subsea infrastructure without exposing human divers to dangerous underwater conditions. ROVs vary in size and capability depending on their task.

Types of ROVs

- Observation ROVs: These are the smallest, typically used for visual inspections at shallow depths of up to 300 meters. Observation ROVs are equipped with cameras and basic tools, mainly for monitoring and gathering data.

- Work-Class ROVs: Larger and equipped with more advanced hydraulic tools such as hydraulic cutters and bolt tensioners, work-class ROVs can operate at depths of up to 3,000 meters or more. These vehicles are essential for heavy-duty tasks such as cutting cables, welding, and structural maintenance.

- Trenching and Burial ROVs: Specialized ROVs used for subsea cable and pipeline installations, trenching ROVs create a trench on the seafloor where subsea infrastructure is laid and buried .

Approximately 60-70% of work-class ROVs are equipped with hydraulic systems that benefit from pressure amplification solutions like mini boosters .

Why Mini Boosters are Ideal for ROV Applications

Mini boosters, as hydraulic pressure intensifiers, allow ROVs to generate significantly higher output pressures even in low-pressure environments. This makes them ideal for operating heavy-duty tools such as hydraulic cutters, crimpers, and bolt tensioners, which require immense force to perform underwater tasks.Benefits of Using Mini Boosters in ROVs

- Compact Size: ROVs have limited space to carry tools, and the mini booster’s compact design allows for easy integration into their systems without adding unnecessary bulk .

- Corrosion Resistance: Built with stainless steel and other corrosion-resistant materials, mini boosters can withstand constant exposure to saltwater, ensuring long-lasting performance in subsea conditions .

- High-Pressure Output: Mini boosters can amplify hydraulic pressure by up to 20 times, making them perfect for high-force operations such as cutting through cables or applying tension to large bolts .

- Energy Efficiency: Mini boosters only increase hydraulic pressure when necessary, leading to up to 30% energy savingsin subsea operations .

- Versatility: Mini boosters can be used with a variety of hydraulic tools, allowing ROVs to perform multiple tasks with a single pressure intensifier .

Applications of Mini Boosters in ROV Operations

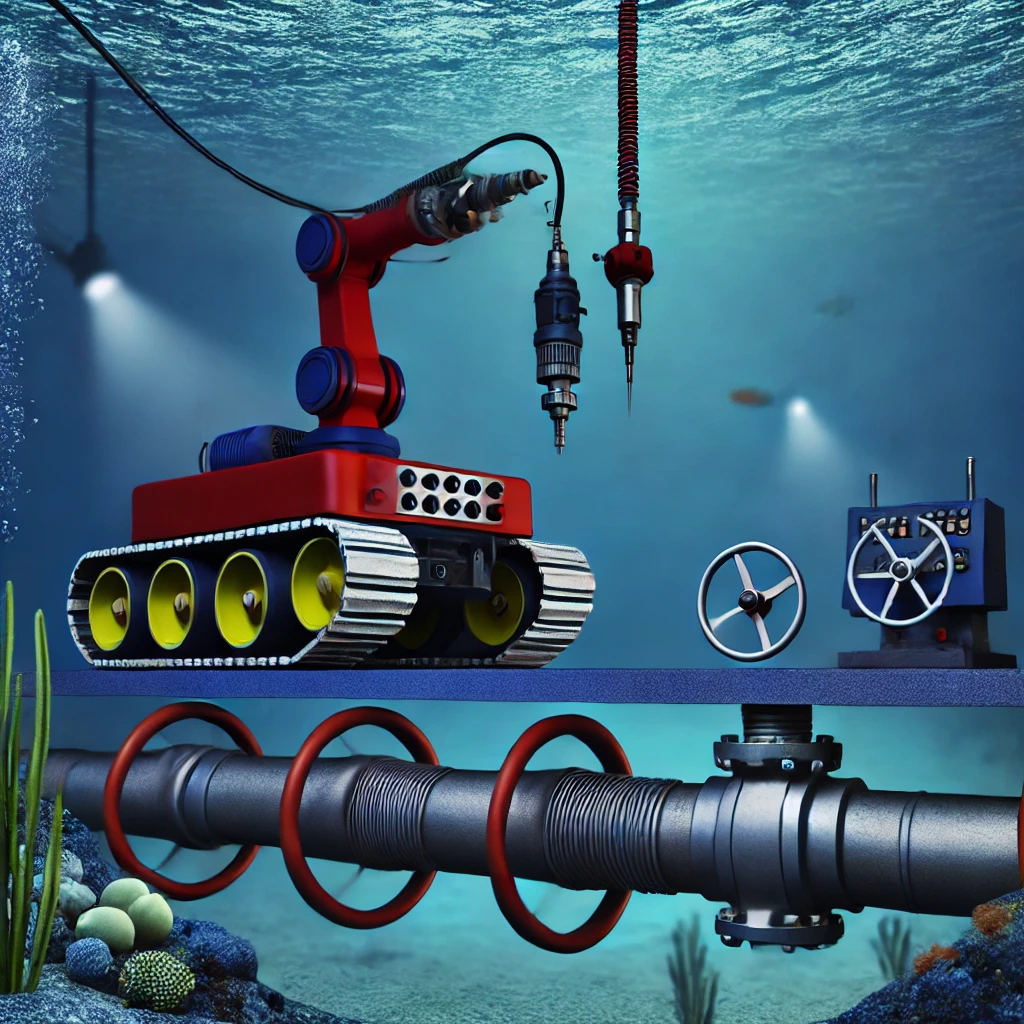

ROVs equipped with mini boosters can perform a wide variety of subsea tasks essential for maintaining and repairing offshore oil platforms:Inspecting Subsea Pipelines and Structures With cameras and hydraulic tools, ROVs inspect underwater pipelines for leaks, damage, or corrosion. Mini boosters provide the necessary pressure to operate these inspection tools .

|

Inspecting Subsea Pipelines and Structures

With cameras and hydraulic tools, ROVs inspect underwater pipelines for leaks, damage, or corrosion. Mini boosters provide the necessary pressure to operate these inspection tools .

Assisting in Installation and Maintenance of Subsea Equipment

During subsea construction, ROVs play a critical role in installing pipelines, connectors, and other equipment. Mini boosters provide the necessary hydraulic pressure to help ROVs position and secure equipment .

Cleaning and Removing Marine Growth

Marine organisms can accumulate on submerged parts of oil platforms, causing degradation. ROVs equipped with hydraulic cleaning tools can remove marine growth, prolonging the lifespan of the structures .

Handling Emergency Repairs

In the event of structural failure or equipment malfunction, ROVs can perform emergency repairs to prevent environmental disasters. Mini boosters provide the hydraulic power necessary for these high-pressure tasks .

ROV Usage in the Oil and Gas Industry

Approximately 75% of all ROVs are engaged in tasks such as Inspection, Maintenance, and Repair (IMR), which are essential for ensuring the structural integrity and functionality of subsea equipment.

In fact, ROVs perform more than 75% of all subsea interventions, solidifying their importance in both routine and emergency scenarios

The use of ROVs in these tasks is particularly valuable as they replace the need for human divers, significantly enhancing safety in the hazardous deep-sea environments where human divers would face extreme pressures, low temperatures, and limited visibility. These vehicles can remain underwater for extended periods and work in depths far beyond human limits, making them indispensable for the industry’s operations

Hydraulic Tools Powered by Mini Boosters

Mini boosters are an integral component in powering a variety of hydraulic tools used by ROVs in subsea operations. These hydraulic tools require extremely high-pressure levels to perform tasks effectively in the deep-sea environment. Mini boosters play a critical role in ensuring that ROVs can operate these tools efficiently and reliably. Some of the most commonly powered hydraulic tools include:

- Hydraulic Cutters: These tools are used to cut through tough subsea cables, pipes, or other materials that need to be removed or replaced. Cutting operations in the deep sea require significant force, and hydraulic cutters powered by mini boosters typically require pressures of up to 10,000 psi (690 bar) to function effectively.

- Bolt Tensioners: Subsea structures, such as those found on oil rigs or underwater pipelines, are often secured with large bolts that must be tightened to a precise tension to ensure structural stability. Bolt tensioners, powered by mini boosters, can generate pressures between 7,000 and 15,000 psi (483 to 1,034 bar), allowing ROVs to tighten bolts to the required specifications.

- Crimping Tools: Used primarily for maintaining or installing cables and connectors, crimping tools are essential for subsea electrical and communication systems. Crimping operations require high pressures, often reaching up to 8,000 psi (552 bar). Mini boosters provide the necessary pressure amplification, ensuring secure and reliable connections.

Corrosion Resistance and Durability

One of the most significant challenges that ROVs and their components face in subsea environments is saltwater corrosion. Saltwater, combined with the high-pressure and low-temperature conditions of deep-sea environments, can rapidly degrade equipment that is not designed for these conditions. Mini boosters, used in the hydraulic systems of ROVs, are built with corrosion-resistant materials such as stainless steel or specially designed alloys. These materials are highly resistant to the corrosive effects of saltwater, ensuring the long-term durability and reliability of the equipment.

Mini boosters can last 10+ years when properly maintained, depending on their operating environment and maintenance schedules. Routine maintenance, which includes inspecting seals, hoses, and connectors, is crucial for ensuring the continued performance of mini boosters in harsh subsea conditions. Their construction is designed to withstand the extreme pressures and mechanical stresses they experience while working in depths of 4,000 to 6,000 meters.

ROV Market Growth

The global ROV market is expected to experience significant growth over the coming years, driven largely by the expanding demand for offshore oil and gas exploration and production activities. This growth is being fueled by increased exploration of deeper oil fields, advancements in subsea robotics technology, and the rising need for safe, cost-effective subsea operations.

The global ROV market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2021 and 2027.

Energy Efficiency and Cost Savings with Mini Boosters

One of the key advantages of mini boosters in ROV hydraulic systems is their energy efficiency. Unlike traditional pressure amplifiers that continuously generate high pressure, mini boosters only increase pressure when it is required for a specific task. This smart pressure management can result in up to 30% energy savings for hydraulic systems, which is a significant benefit in subsea operations where energy efficiency is critical. The energy efficiency of mini boosters not only reduces operational costs for companies using ROVs but also extends the lifespan of hydraulic tools. By generating high pressure only when needed, mini boosters minimize wear and tear on the hydraulic system’s components, such as seals, hoses, and valves. This leads to fewer repairs and replacements, which in turn reduces the downtime of ROVs, ensuring that they remain operational for longer periods and improving overall productivity.Extreme Depth Capabilities

As offshore oil and gas exploration moves into deeper waters, the need for ROVs that can operate in ultra-deep environments is growing. Some of the latest ROVs equipped with mini boosters can function effectively at depths ranging from 4,000 to 6,000 meters (13,123 to 19,685 feet). At these depths, the water pressure is immense, reaching up to 600 bar (8,700 psi) or more, which places enormous stress on both the ROVs and their hydraulic systems. Mini boosters enable ROVs to deliver precise hydraulic pressure at these extreme depths, allowing them to perform complex tasks that would otherwise be impossible. Whether cutting through thick cables or applying tension to critical components of subsea infrastructure, mini boosters ensure that ROVs have the power needed to maintain and repair equipment in these extreme environments. ROVs operating at these depths are crucial for industries such as oil and gas, as well as subsea mining and underwater construction. The ability to operate autonomously at such depths reduces the need for manned submersible vehicles, increasing the safety and efficiency of subsea operations. Additionally, with advancements in technology and materials, mini boosters are expected to continue playing a vital role in the evolution of ROV capabilities.The Future of ROV Technology and Mini Boosters

ROVs and mini boosters are continuously evolving to meet the challenges of deeper and more complex subsea environments. Next-generation ROVs are expected to incorporate artificial intelligence (AI for autonomous decision-making, further reducing the need for human operators . These AI-driven ROVs will rely on compact, efficient hydraulic systems like mini boosters to perform tasks with minimal human intervention. In addition to AI, advancements in materials science are enabling the development of even more durable, corrosion-resistant ROVs. The future of subsea operations will likely see ROVs equipped with smart sensors and real-time monitoring systems, ensuring safe and efficient operation even in extreme conditions .References

- International Association of Oil & Gas Producers (IOGP). Offshore Rig Depths.

- National Oceanic and Atmospheric Administration (NOAA). Deep-Sea Pressures and Environments.

- miniBOOSTER Hydraulics A/S. Technical Specifications on Corrosion Resistance.

- Saab Seaeye. Observation ROV Specifications.

- Oceaneering International. Work-Class ROV Systems Overview.

- Trenching and Burial ROV Technology Overview, Offshore Magazine.

- Global Subsea Technologies Report, 2023.

- miniBOOSTER Hydraulics A/S. Compact Hydraulic Pressure Intensifiers.

- Offshore Technology Reports on Corrosion-Resistant Materials in Subsea Equipment.

- miniBOOSTER Hydraulics A/S. High-Pressure Output for Subsea Operations.

- Hydraulic Systems Energy Efficiency in Offshore Applications, Industry Report 2022.

- Oceaneering International. Hydraulic Systems for ROVs.

- Inspection ROV Tools for Subsea Pipelines, Subsea World News.

- Offshore Valve Repair and Maintenance with ROVs, Oil & Gas Journal.

- Installation and Maintenance of Subsea Equipment Using ROVs, Marine Technology News.

- Marine Growth Removal Techniques for Oil Platforms, Offshore Engineer Magazine.

- Emergency Repairs with ROVs in Offshore Operations, Journal of Subsea Engineering.

- AI and Autonomous ROVs in Offshore Operations, Robotics Industry Insights.

- Future Trends in ROV and Subsea Technologies, Subsea World News.