MiniBOOSTER Hydraulic Intensifier HC75-20.0-A-13

- Payment by invoice possible

- Not currently in stock, contact us for factory lead times

- Payment by invoice possible

- In stock at factory, ready to ship in estimated 1-2 weeks, contact us for expedited options

- Del Rey is proud to be the exclusive distributor of Waagene products

- Payment by invoice possible

- Low quantities typically kept on hand; please contact us for availability at lead time

- Authorized MiniBOOSTER distributor & hydraulic excellence partner

Product Description

The HC75 – 20.0 – A – 13 is a lightweight unit at 2.8 kg/ 6.1 lbs, designed for applications requiring high-pressure maintenance. Featuring a counterbalance valve, it facilitates rapid cylinder movement by directing full inlet flow through the booster until reaching the set pressure. Automatic stall occurs upon reaching the high-pressure side, with continuous compensation for oil consumption. Outlet pressure adjustment is achieved by varying the supplied pressure, with an optional orifice available to prevent overspeeding.

Additional information

Product specification

- HC75 versions: 10 different intensification factors.

- PIN: 20 – 207 bar.

- PH: 2,000 bar maximum.

- PRETURN: As low as possible (return pressure to tank).

- POUTLET: PH = (PIN – PRETURN) x intensification factor.

- Mounting: Inline tube.

- Weight: 2.8 kg/ 6.1 lbs.

Model versions

- A model = no dump valve.

- B model = with dump valve.

Material certificate 20.0 on request

Flow Rates

| Intensification Factor i | Max.Intensified Outlet flow i/min | Max. Inlet flow i/min |

|---|---|---|

| 4.0 | 2.0 | 14.0 |

| 5.0 | 1.6 | 14.0 |

| 6.6 | 1.3 | 13.0 |

| 7.6 | 1.1 | 13.0 |

| 9.0 | 0.9 | 13.0 |

| 10.3 | 0.8 | 12.0 |

| 13.0 | 0.6 | 12.0 |

| 16.0 | 0.5 | 12.0 |

| 20.0 | 0.3 | 12.0 |

| 25.0 | 0.2 | 12.0 |

Function description

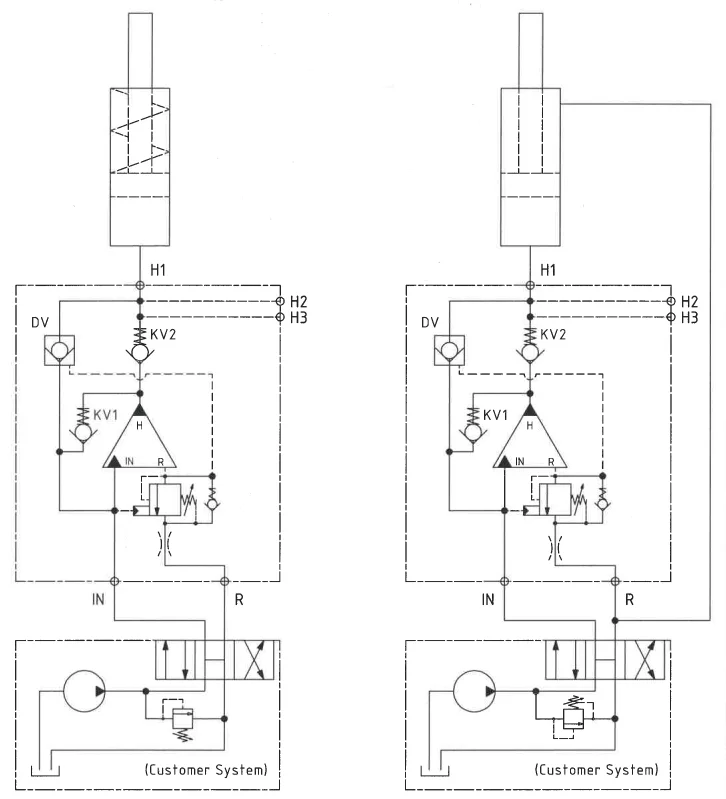

The basic operation is illustrated in the function diagram. Oil is fed through the directional valve (in the customer system) to the IN port, flowing freely through the internal check valves to the high-pressure side H. When pump pressure is reached on the high-pressure side H, the internal check valves will close. The end pressure will be achieved by the oscillating pump unit OP. The unit will automatically stall when the high-pressure side H is reached. If a pressure drop on the high-pressure side exists due to consumption or leakage, the OP valve will automatically operate to maintain the end pressure.

Function diagram

Function diagram HC75-20.0-A-13

Dimension

Dimension drawing HC75-20.0-A-13

Connection Types

| Connection | IN/R | H1 | H2 | H3 |

|---|---|---|---|---|

| 11 | 1/4″ BSPP | M22 x 1.5 | – | – |

| 12 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | – |

| 13 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF |

Ordering an HC75

Ordering example of an HC75 with i = 20.0, H1 M22 x 1.5 and H2 9/16-18 UNF, DV incorporated and BSPP connections: HC75 – 20.0 – A – 13

Attention note!

High-pressure adapter is required, please specify ordering code – see high-pressure adapter table.

High-pressure adapters will be factory mounted.

Valve pre-setting is required, please specify when ordering the intensifier.

Model

- HC75

Intensification,

- Select factor

- See flow rate table

Model Version.

- Select type

- A = without DV

- B = with DV

Connections

- Select thread

- See table below

| Ordering code | IN/R | H1 | H2 | H3 |

|---|---|---|---|---|

| HC75-___-__-11 | 1/4″ BSPP | M22 x 1.5 | – | – |

| HC75-___-__-12 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | – |

| HC75-___-__-13 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF |

Max. tightening torque BSPP

| IN / R | |

| 1/4″ BSPP | |

| with steel washer | 4.0 da/Nm |

| with cutting edge | 4.0 da/Nm |