22

Feb

Enhancing Industrial Efficiency with Pressurized Oil Purification Systems

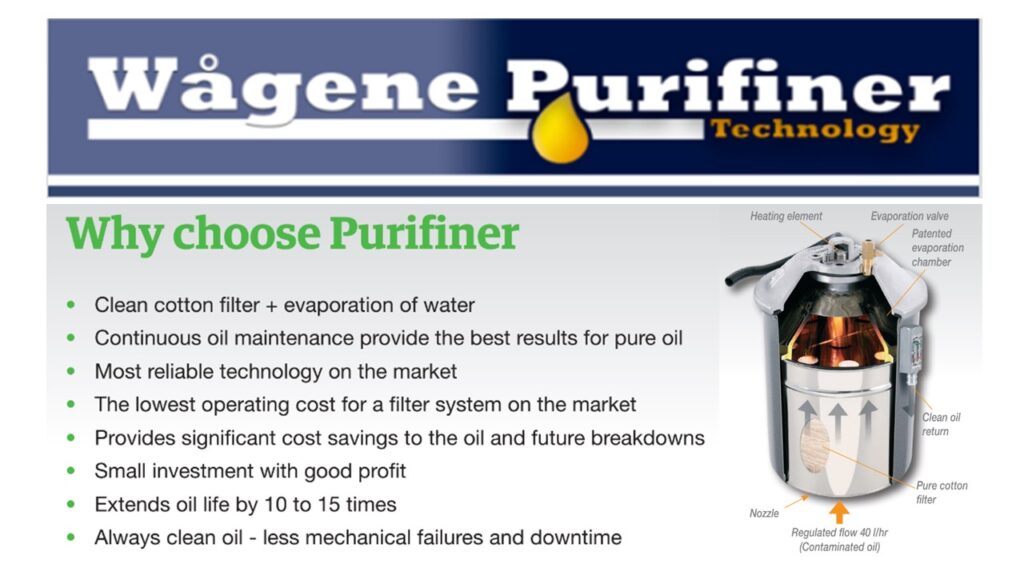

The importance of maintaining oil purity in industrial equipment cannot be overstated, as it directly impacts operational efficiency, equipment longevity, and maintenance costs. Waagene Purifiner Technology has developed a series of pressurized oil purification systems designed to meet the rigorous demands of modern industries. From the TS unit to the innovative TS-Triple, these systems offer a comprehensive solution for maintaining oil purity in pressurized environments.

Introducing the Purifiner Pressurized Systems

Waagene’s lineup of pressurized oil purification systems is engineered for optimal performance in diverse industrial settings. These systems are specifically designed for hydraulic oils but possess the versatility to clean almost all types of oil. The key feature of these units is their ability to integrate seamlessly with pressurized systems, ensuring continuous purification without disrupting operations.

Key Products in the Pressurized Systems Range

Purifiner TS Unit:

The foundational model in the range, designed for direct connection to hydraulic systems, making it ideal for applications where the cleaning unit is placed lower than the system it cleans.

Purifiner TS-Twin:

Doubling the capacity of the TS unit, the TS-Twin offers enhanced performance for larger systems, maintaining the same high standards of oil purification.

Purifiner TS-Triple

With triple the capacity of the original TS unit, the TS-Triple is suited for extensive hydraulic systems requiring a high volume of oil purification.

Purifiner Mobile:

Offering the same capacity as the TS5060PMH but mounted on a trolley for mobility, this unit is designed for flexibility in maintenance and spot cleaning.

Trending Insights

Products Categories

Purifiner Control Unit:

A specialized bypass unit for construction machinery, allowing for external filter connection and direct mounting on the machine for efficient oil purification.

Advantages of Waagene’s Pressurized Oil Purification Systems

Implementing Waagene’s pressurized oil purification technology offers numerous benefits, including the extension of equipment life, reduction in maintenance downtime, and significant cost savings on oil replacement and disposal. These systems ensure continuous purification of hydraulic oils, enhancing the performance and reliability of industrial machinery.

Case Studies and Real-World Applications

Although specific case studies were not detailed, the diverse range of Waagene’s pressurized systems suggests their applicability across various industrial sectors. From manufacturing to construction, these purification systems are instrumental in maintaining operational efficiency, preventing equipment failure, and ensuring environmental compliance through reduced oil waste.

Conclusion: Leading the Way in Oil Purification Technology

Waagene Purifiner Technology’s pressurized oil purification systems represent a significant advancement in industrial maintenance. By offering a robust solution tailored for pressurized environments, these systems not only safeguard the longevity of machinery but also contribute to a more sustainable and cost-effective operational model. Whether through the TS unit, TS-Twin, TS-Triple, Mobile unit, or Control Unit, Waagene provides the tools necessary for industries to maintain peak efficiency and reliability in their operations.